Nichia's contribution to a realization of a mercury-free society

Nichia's contribution to a realization of a mercury-free society

22 Oct 2024

Alternative Technologies to Low-pressure Germicidal Mercury Lamps for Water Disinfection Applications

The prior blog titled “Nichia’s contribution to a realization of a mercury-free society” took a short break. However, there was a release about new LED-based water disinfection devices made by Miura Co., Ltd., a Japanese manufacturer and also one of Nichia’s customers, that has successfully been replacing mercury lamp systems. By using the features of this device as an example, Nichia would like to explain in this blog the reason for why it was possible for the manufacturer to replace mercury lamps with LEDs, and the advantages of utilizing LEDs.

While there are a variety of lamps containing mercury, the focus for this blog is the low-pressure mercury lamp, also known as a germicidal lamp.For example, in food and pharmaceutical factories, they have been used to disinfect water in cleaning products and equipment that keep in contact with products.

At a light source level only (not system level), the energy conversion efficiency of low-pressure mercury lamps is approximately 20% to 30%. Whereas UV-C LEDs, again just focusing on the light source, the energy conversion efficiency is inferior to mercury lamps. This has perhaps made the resistance to the adoption of UV LEDs higher than necessary as it is not a logical comparison by itself. The RoHS Directive exempts mercury lamps from regulation due to the “lack of alternative technologies.” However, considering not only the energy conversion efficiency figures of the light source, but also the advantages of LEDs, LEDs already possess the capability to be an alternative technology with their current performance. In fact, water disinfection devices equipped with UV LEDs have already been installed in many factories worldwide.

Figure 1. Examples of Irradiation

As shown in Figure 1, conventional water disinfection devices have pipes surrounding low-pressure mercury lamps that emit UV light in all directions. This causes the UV light to immediately hit the inner walls of the device, wasting valuable UV radiation, and lowering the efficiency of UV utilization.

On the other hand, UV LEDs are so compact, allowing flexible layouts without limitations on the shape of devices. This enables designs to maximize efficiency of UV utilization, thus achieving sterilization effects equivalent to low-pressure mercury lamps.

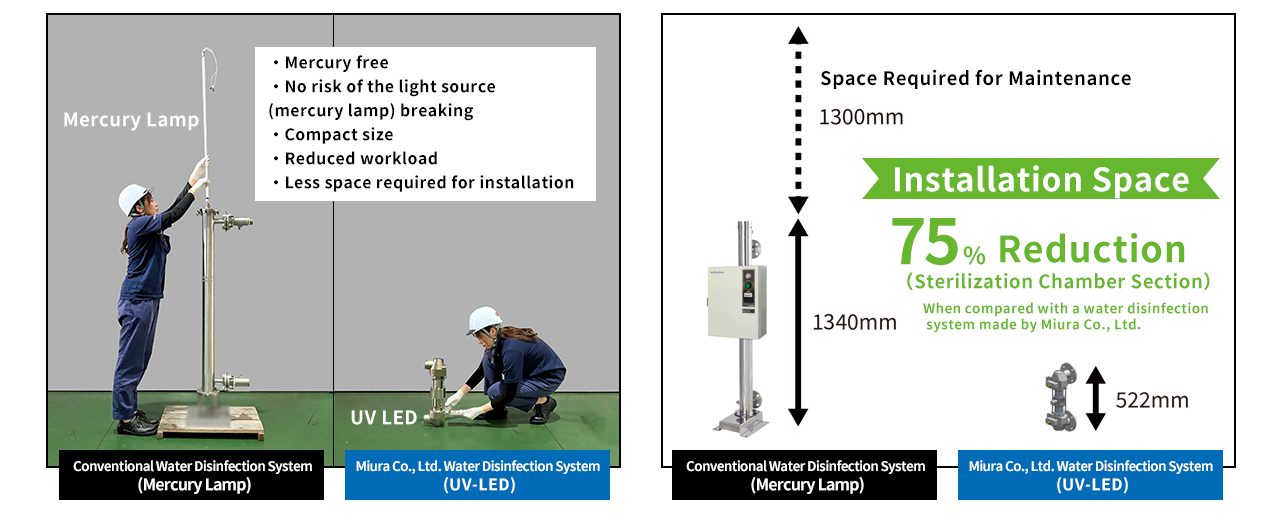

Replacing the vertically long low-pressure mercury lamps with UV LED light source also allows for miniaturization of the device and reduces the space necessary for light source replacement, cutting the space required for installation by 75%. With mercury lamps there is always the risk of the lamp breaking during replacement and causing glass or mercury to spread; there is no such risk with UV LED light sources, thus eliminating installation constraints and allowing for flexible and usage.

Figure 2. Make Maintenance Work Easier and Reduce the Space Necessary to Install

Once turned off, low-pressure mercury lamps require a long time to restart, so they need to be kept on constantly. However, LEDs can be switched on and off instantly, and the power can be turned off only when the water flow is temporarily not in use or disinfection is not necessary.

Furthermore, when flow rate is relatively low, the necessary amount of UV radiation can also be reduced in accordance with the flow rate. LEDs capability to be dimmed makes it possible to adjust the radiant flux output. These features of UV LED help reduce energy consumption, and as a result, decrease CO2 emissions.

Table 1. Comparison Results of Low-pressure Mercury Lamps and UV LEDs

| Mercury Lamp1 | UV LED | |

|---|---|---|

| Efficiency | 20%~30% | 5.4% |

| Device Size | 320mm (W) × 1,340mm (H) × 405mm (D) | 158mm (W) × 522mm (H) × 223mm (D) |

| Instantaneous On/Off | Not Possible | Possible |

| Power Consumption | 220W (Processing Quantity: 6m3/h) |

157W (Processing Quantity: 8m3/h) |

| Sterilization Ability (Bacillus subtilis spores) |

More than 99.9% | More than 99.9% |

1 A water disinfection system made by Miura Co., Ltd.

Summary:

In this case study, even though the energy conversion efficiency at the LED light source may seem insufficient compared to mercury lamps, it has become clear that LEDs can serve as an alternative in water disinfection applications by maximizing the use of UV LED by utilizing their unique features. Additionally, the transition to UV LEDs offers numerous benefits, such as reducing the space required for installation and shortening the operating time with instant on/off capabilities.

Nichia will continue to advance UV LED technology so that, beyond the water disinfection applications introduced here, UV LEDs can be used as an alternative to low-pressure mercury lamps in all sterilization fields. Nichia hopes this progress will make the extension of the RoHS Directive exemption beyond 2027 unnecessary, further reducing the negative environmental impact of those fields.

Nichia will continue to make an effort to solve social issues such as the realization of a mercury-free and carbon neutral society.